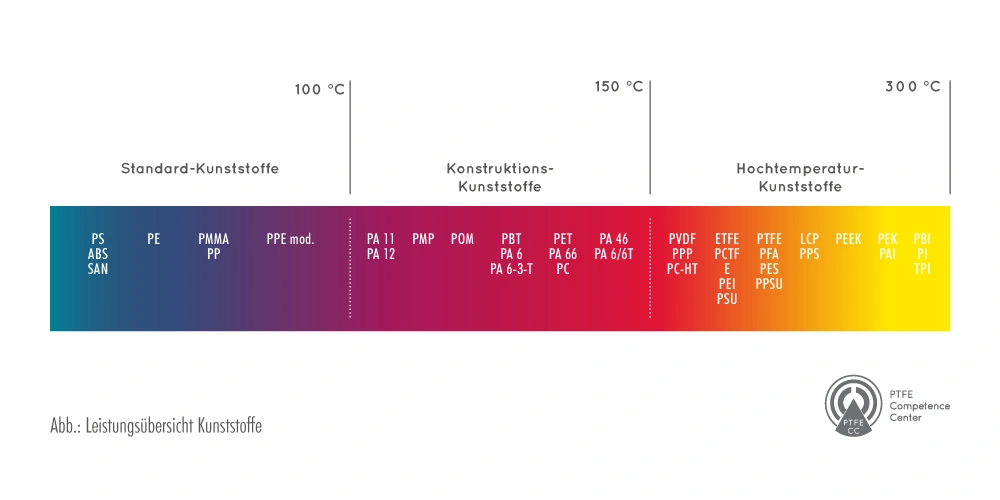

A world without plastics is unimaginable today. Owing to their exceptional properties, plastic structural components have already ousted conventional components made of steel or glass from many industry areas and sectors. Since not all plastic parts can be manufactured using injection molding techniques, structural components are produced with CNC-controlled lathes and milling machines. The correct selection of a material is a crucial step in the product creation process. We can help you to select the appropriate material individually to meet your specific requirements.

Competence in plastics

Since producing materials tailored to your needs is what we want to achieve, we process the following materials among others

- Polyethylene (PE), one of the most frequently used plastics for foils and packaging or simple injection cast components

- Polypropylene (PP), a very variably applied material. Important fields of application are packaging foils and rigid packagings. PP is also used as a material for housings of electrical and household devices and for body panels in vehicle construction. PP has moreover found application in pipeline construction.

- Polyamides (PA), characterized by their high mechanical strength, are often used in vehicle construction.

- Polyoxymethylene (POM), a very versatile plastic material that is the first choice for several structural components.

- Polyphenylsulfone (PPSU), a temperature and impact resistant plastic material used in the aerospace industry, vehicle construction and also in electrical engineering.

- Polyvinylidene fluoride (PVDF), commonly used in electrical and medical engineering for seals, membranes, in pumps or valves.

- Ethylene tetrafluoroethylene (ETFE), for example is used in architecture.

- Polychlortrifluorethylene (PCTFE), known for its extreme form stability, is used in pumps, compressors and refrigeration technology.

- Polyetherketone (PEEK), numerous application areas in vehicle construction or high voltage engineering, but also in the pharmaceutical and chemical industries.

You have the requirements. We have the necessary know-how to find the appropriate technical solution.

We look forward to your request!

Do you have a specific question about our competence in plastics?

Please use our request form or get into contact with us directly.