Solid rods can be manufactured using special pressing and sintering technologies. The semi-finished products are manufactured with respective allowances. These allowances are set such that as little waste as possible is pro-duced during machining while at the same time ensuring that the finished part contour can be manufactured without problems. PTFE CC GmbH has a narrowly graded tools park to achieve an optimal ratio between the dimensions of the semi-finished product and that of the finished component. Due to the varying material-related shrinkage that occurs (there are marked differences between pure PTFE, modified PTFE and PTFE compounds), slight variances in the dimensions of the semi-finished products are possible even when working with the same tool dimensions. For this reason, we do not work with semi-finished listings, but adapt the dimensions of the semi-finished product to your finished product dimensions.

Solid rods

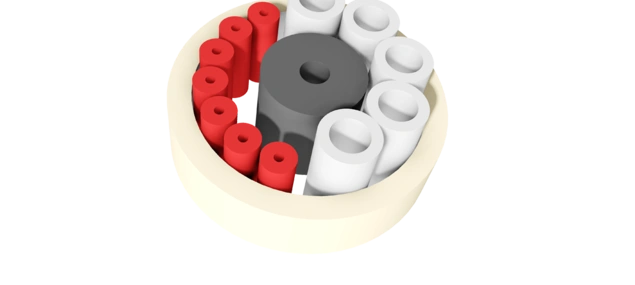

Pressed solid rods

Extruded solid rods

During a process called RAM extrusion, a periodically moving punch presses the PTFE powder batchwise through a heated tube. The pressing force required for the compression is realized by wall friction or, additionally, by a brake. Several heat zones along the extrusion tube and a special temperature profile ensure that the PTFE rod is sintered through fully. The design is generally determined by the shape of the extrusion cylinder. Using RAM extrusion, rod-shaped solid rods can be manufactured quasi-continuously and economically. Please note that only standard mate-rials such as pure PTFE, PTFE/glass fiber or PTFE/carbon are extrudable. The standard lengths are 1 m to 2 m.

Get your product quickly!

To help you quickly and easily find the best solution for your products, please send us your product inquiry via the form below. So you can send us your specifications and requirements directly.

Discover our product competence.

With our products navigator you can get to the product you are looking for quickly.