The internal sealing rotary seal type RI is used as a double-acting seal for rotary unions, axes, actuators and shafts. The media used in these applications range from mineral oil-based hydraulic liquids, environment-friendly bio-oils and water to flame-resistant hydraulic liquids and air.

To create a lubricant reservoir and increase the surface pressure against the rod, one or two circumferential notches, depending on the profile cross section, are worked into the running surface of the PTFE profile ring.

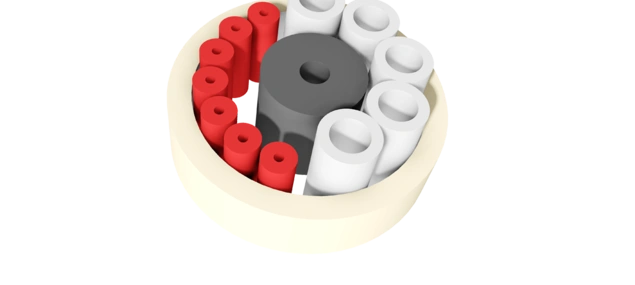

With the PTFE profile ring, the rotary seal dynamically seals off the rod surface, and with the elastic O-ring, provides a static sealing between the profile ring and the groove base.

With different material combinations, it can be used reliably across the whole pressure, speed and temperature range while additionally ensuring stick-slip free running.