Back-up rings are manufactured from extrusion resistant material as protection and support elements, normally with a rectangular cross-section.

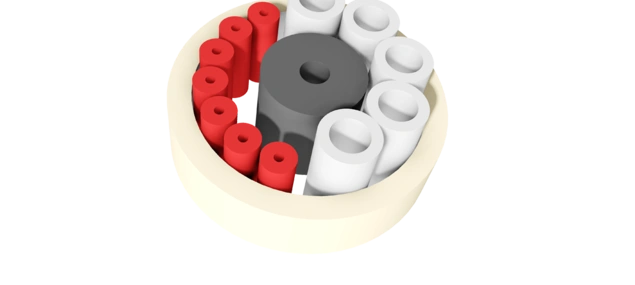

For static applications they are used together with an elastomer seal – usually an O-ring – placed in the groove.

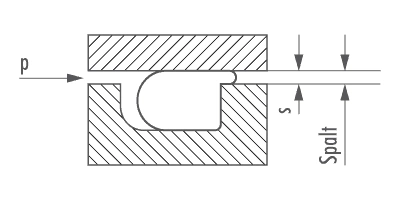

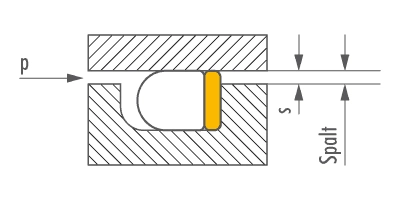

Because there is a tight fit between back-up ring and bore hole or rod it prevents the O-ring from extruding into the sealing gap under pressure.

Back-up rings

Gap extrusion destroys the O-ring

Back-up ring supports the O-ring

Back-up rings can be used in static applications as well as in translational movements or slow rotations.

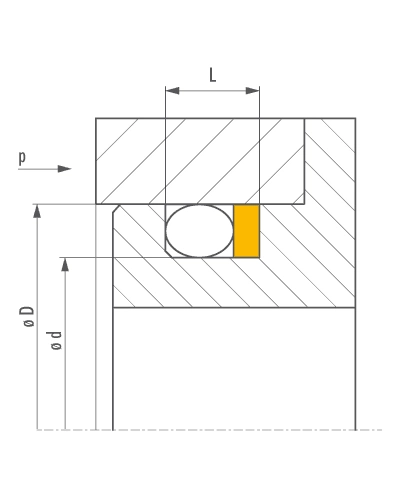

If the pressure is one-sided, it is sufficient to install the seal on the side opposite the pressure.

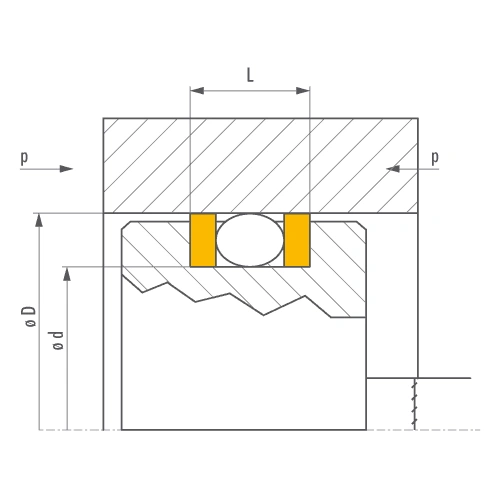

With pressurization on alternate sides, two back-up rings should be used, one back-up ring on each side of the O-ring.

O-ring installation clearance details and recommendations

Pressure direction <->

Pressure direction ->

Pressure direction <->

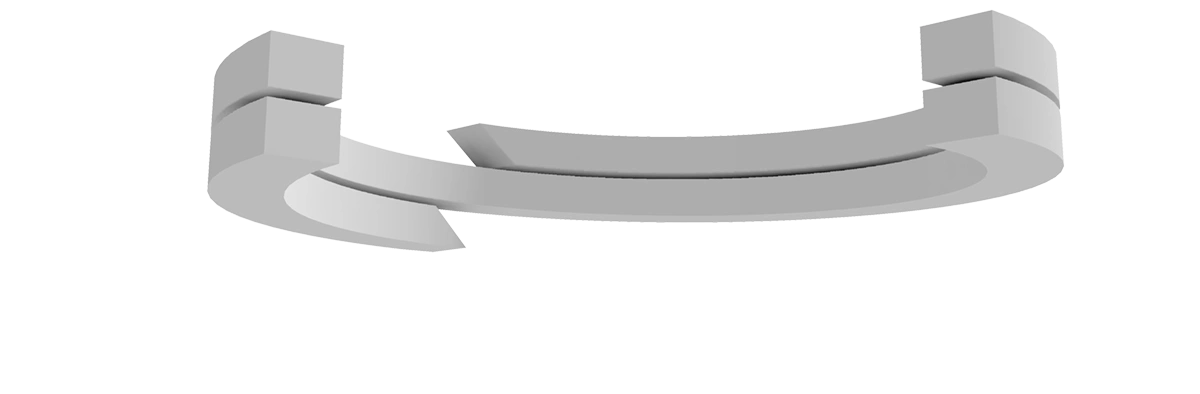

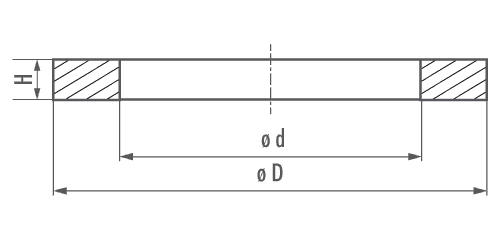

Back-up ring SUv

– Rectangular profile

– For static and back and forth movements or slow rotations

Back-up ring SG

– Rectangular profile, split

– As alternative to unsplit back-up rings if these cannot be installed or in case a split groove is not possible

– For static and back and forth movements

– Oblique cut at 30° or 45° angles, the back-up ring is cut chipless so that there will be no gap when installed.

Back-up ring SKU

– Concave profile

– Mainly for static applications, possible use in back and forth movements

– Protects the O-ring against extreme deformations during pulsating pressures due to the larger contact surface.

– The form stability of the O-ring has a favorable influence on leak tightness and service life

Back-up ring SKG

– Concave profile, split

– Mainly for static applications, possible use in back and forth movements

– Protects the O-ring against extreme deformations during pulsating pressures due to the larger contact surface.

– The form stability of the O-ring has a favorable influence on leak tightness and service life

– As alternative to the unsplit SKU back-up rings if these cannot be installed or in case a split groove is not possible

Back-up ring SP

– Back-up ring, spiral form

– As alternative to unsplit back-up rings if these cannot be installed or in case a split groove is not possible

– For static and back and forth movements

– Oblique cut at 30° or 45° angles

– Application under large temperature fluctuations

– Large tolerance variations are compensated through spiral contraction and expansion

Back-up ring SUQ

– Special designs made of PTFE (snap-back, quenched)

– Easy installation in enclosed groove areas due to the recovery property of the PTFE material

– Because the dimensions deviate from standard designs, these back-up rings are manufactured only on request based on drawings

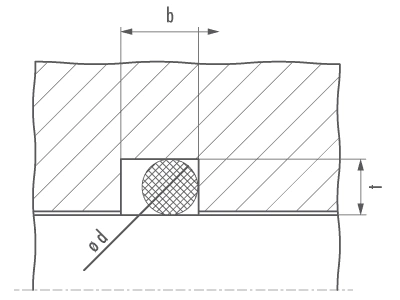

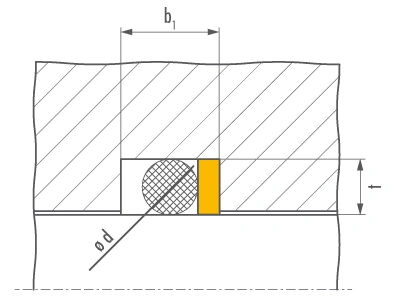

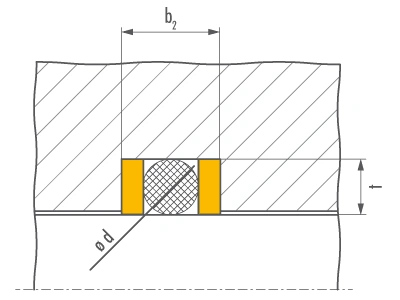

O-ring installation groove dimensions for static applications

| cord strength (mm) | droove depth (mm) | w/o back-up ring (mm) | 1 back-ring (mm) | 2 back-ring (mm) | recommended back-up ring width (mm) |

|---|---|---|---|---|---|

| ø d | t ± 0,05 | b + 0,25 | b1 + 0,25 | b2 + 0,25 | |

| 1,50 | 1,10 | 2,10 | 3,10 | 4,10 | 1,00 |

| 1,78 | 1,35 | 2,50 | 3,50 | 4,50 | 1,00 |

| 2,00 | 1,56 | 2,70 | 4,20 | 5,70 | 1,50 |

| 2,50 | 2,05 | 3,30 | 4,80 | 6,30 | 1,50 |

| 2,62 | 2,18 | 3,50 | 5,00 | 6,50 | 1,50 |

| 3,00 | 2,52 | 3,90 | 5,40 | 6,90 | 1,50 |

| 3,50 | 3,00 | 4,40 | 5,90 | 7,40 | 1,50 |

| 3,53 | 3,00 | 4,40 | 5,90 | 7,40 | 1,50 |

| 4,00 | 3,40 | 5,00 | 6,70 | 8,40 | 1,70 |

| 5,00 | 4,25 | 6,30 | 8,00 | 9,70 | 1,70 |

| 5,33 | 4,53 | 6,70 | 8,40 | 10,10 | 1,70 |

| 5,70 | 4,85 | 7,10 | 9,10 | 11,10 | 2,00 |

| 6,00 | 5,10 | 7,50 | 9,50 | 11,50 | 2,00 |

| 6,99 | 5,94 | 8,80 | 10,80 | 12,80 | 2,00 |

| 7,00 | 5,95 | 8,80 | 10,80 | 12,80 | 2,00 |

| 8,00 | 6,80 | 10,00 | 12,50 | 15,00 | 2,50 |

| 10,0 | 8,50 | 12,50 | 15,00 | 17,50 | 2,50 |

Further application information:

The risk of gap extrusion is typical under high pressures or with small ring cross sections in static but also dynamic applications.

A back-up ring must always be used together with an O-ring. The back-up ring itself provides no sealing.

Materials

- TFE pure (CCN-01), standard material

- PTFE + bronze

- PTFE + glass fiber

- PTFE + carbon

- POM, PA, PEEK …

Application limits

> depends on back-up ring material and sealing gap

DYNAMIC APPLICATIONS

- Translational motions: approx. up to 40 MPa

- Rotation: approx. up to 15 MPa

- Operating temperature: -200 °C to +200 °C

STATIC APPLICATIONS

- Approx. up to 250 MPa working pressure

- Speed: approx. up to 2 m/s

Get your product quickly!

To help you quickly and easily find the best solution for your products, please send us your product inquiry via the form below. So you can send us your specifications and requirements directly.

Discover our product competence.

With our products navigator you can get to the product you are looking for quickly.